Muovitech group is the European leader of products for geothermal energy, the headquarter is in Borås (Sweden) where the first plant was established; other factories are in US, Finland, Poland, Netherlands, UK and Norway.

For more than 15 years Muovitech has been developing and manufacturing in its factories all installation products for geothermal energy systems, for private and commercial sector. Their innovative products for heating and cooling contributes to a better climate on Earth and to the reduction of carbon emissions.

For more than 15 years Muovitech has been developing and manufacturing in its factories all installation products for geothermal energy systems, for private and commercial sector. Their innovative products for heating and cooling contributes to a better climate on Earth and to the reduction of carbon emissions.

The TurboCollector ® represents the latest invention for geothermal probes, a highly advanced patented technology that allows, through inner helicoidal fins, a turbulent flow and guarantees a better thermal exchange with the ground than a normal probe ( smooth inside).

CONDUCTIVITY / RESISTANCE

CONDUCTIVITY / RESISTANCE

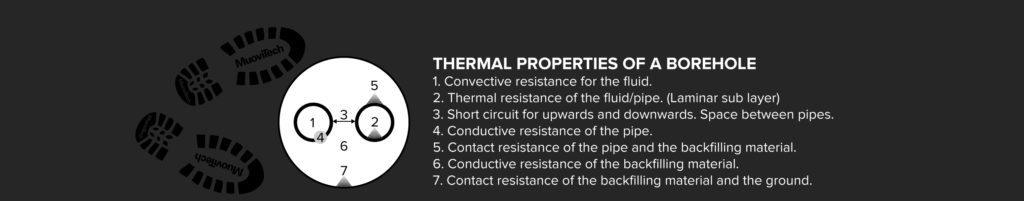

The amount of heat that can be transferred between surrounding ground and heat carrier fluid depends on the two thermal properties: the thermal conductivity of the soil and the thermal resistance of the borehole. The soil quality is usually related to geological situation which cannot be changed by planer but borehole thermal resistance can be engineered and must be kept as low as possible.

The amount of heat that can be transferred between surrounding ground and heat carrier fluid depends on the two thermal properties: the thermal conductivity of the soil and the thermal resistance of the borehole. The soil quality is usually related to geological situation which cannot be changed by planer but borehole thermal resistance can be engineered and must be kept as low as possible.

DECREASE THERMAL RESISTANCE

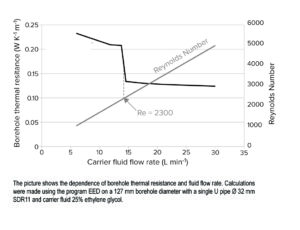

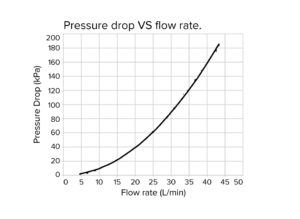

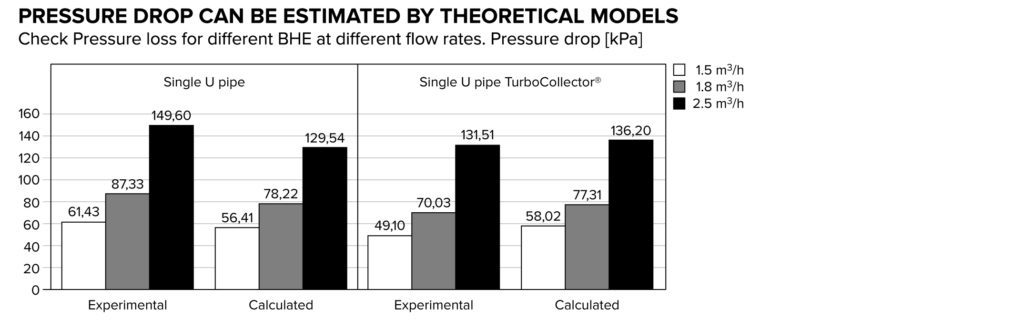

The picture up to the right shows that higher flow rate can improve the performance of the system by decreasing the borehole thermal resistance. However this advantage is tradeoff by higher energy consumption of the circulation pump. The circulation pump must overcome the system’s pressure drop. It means a bigger pressure loss, a larger circulation pump is required and greater pump power consumption.

The picture up to the right shows that higher flow rate can improve the performance of the system by decreasing the borehole thermal resistance. However this advantage is tradeoff by higher energy consumption of the circulation pump. The circulation pump must overcome the system’s pressure drop. It means a bigger pressure loss, a larger circulation pump is required and greater pump power consumption.

A GOOD GSHP SYSTEM HAS THE FOLLOWING CHARACTERISTICS:

- Has high heat exchange efficiency with the surrounding heat source (with low borehole thermal resistance) particularly at the peak load.

- Has a turbulent flow regime in the system for the higher heat transfer.

- Has an acceptably low pressure drop to minimize circulation pump power consumption.

RESULTS

There are several important factors in GSHP systems. Among of them is the flow rate of the secondary fluid of the ground side. Flow rate can significantly effect on pressure drop and also on pump energy consumption. Heat exchange characteristics of a collector with trubulator (TurboCollector®) in a passive mode with smooth collectors in different arrangement were evaluated. Results indicate that micro fins can contribute to better heat transfer and pipes with the inner

finned improve the performance of the system by lower borehole thermal resistance. This type of collectors can be applied for both cooling and heating mode meanwhile the flow rate can be set in a lower value compared to the smooth pipes. Moreover, the pressure drop in the collectors with turbulent promoter can be estimated by theoretical models.

CERTIFICATES

P-mark by SP SITAC. SC1106-11. INSTA SBC 12201 EN 12201:2003.

SKZ A 759.